FAQs

- When was Burris Optics founded?

- What are your hours?

- Where can I buy Burris Optics products?

- Do you offer Military & LEO discounts?

- How do I send in my Burris Optic for repair?

- Are all Burris scopes waterproof, fogproof, and shockproof?

- What type of battery does my optic use?

- What should I use to clean my optics?

- Can my scope be refinished?

- How are Burris Optics coated?

- How do I mount my scope?

- How do I focus my scope?

- How do I know how much to tighten the rings and bases?

- How to mount and sight in the Oracle X.

- How do I mechanically center my scope?

- What is the difference between Front & Rear Focal Plane?

- My scope adjustments are maxed out. How do I obtain more adjustment?

- Can I use heat cure Cerakote on my scope tube?

- Can I store my weapon in my vehicle with a scope mounted?

- How to mount and sight in the Oracle 2.

- Why does my reticle move down when my turret says UP?

When was Burris Optics founded?

History

The Burris Company was formed in 1971 and named after its founder Don Burris. Burris was a design engineer with Redfield, a Denver-based optics company, who believed he could build a better riflescope than what was currently available.

During his 12-year career with Redfield, he focused on product design and management and was responsible for many industry innovations such as:

- The first constantly centered non-magnifying reticle in variable power scopes. a design used in 99% of all scopes today

- The first 4-12x and 6-18x riflescopes

- The Redfield Accu-Range trajectory compensating dual reticle scope

- The Redfield Wideview riflescope

During the company’s first four years, Don Burris’ new company produced rings, bases, and open sights, but it wasn’t long before he was back to the design and manufacture of sporting optics. The company’s first optic was a riflescope called the Fullfield, which he began to market in 1975 and it has grown to be an industry icon that is still manufactured today.

Although Don Burris passed on in 1987 the company that bears his name continued to grow and be the first to market with a number of innovative products. It was acquired by Beretta Holdings in 2002 and became part of the Beretta family of companies. Today, the company’s product line includes hunting and tactical riflescope scopes, red-dot and reflex sights, and a complete line of rings and bases.

Burris Company Timeline 1971

1971

Established and named after its founder, Don Burris

1975 – 1978

Introduced the Fullfield riflescopes series and designed to greatly exceed the performance of the-then most popular Redfield Wideview scope. During this period, the Fullfield line grew to include magnification ranges from 1.75 -5x to 6-18x

1979

Burris launches Compact and Handgun scopes

1980

Offers the first American made scopes with multi-coated lenses to optimize light transmission.

1981

Launches the now-famous Zee Rings, which are the most fail-proof of any rings to fit Weaver-style bases

1983

Introduced the industry’s first variable power handgun scope

1988

Introduced the industry’s first Scout Scope

1993

Developed the patented Posi-Lock® system that eliminated any binding or thread backlash in the adjusting system to absolutely assure repeatable accuracy.

1995

Introduced the Signature Rings, which gave shooters the ability to sight in his gun using just the rings.

2000

The Ballistic Plex™ reticle with trajectory compensation is introduced along with the world’s first titanium riflescope - Burris Black Diamond Titanium™

2002

Burris is acquired by Beretta.

2006

Introduced the first LaserScope that instantly provided distance to your target.

2007

Launched the FastFire, a mini red dot reflex sight that has become the choice of hunters and tactical shooters to this day.

2010

The revolutionary Burris Eliminator changes the optics market with its laser rangefinder and automatic BDC capabilities

2014

The premium line Veracity riflescopes is introduced to the hunting market. Featuring front focal plane reticles, zero click stop adjustments and a 5x zoom system.

2015

New XTR Signature Rings™ with Pos-Align® offset Inserts bring the same benefits tactical shooters that hunters have enjoyed for years.

What type of battery does my optic use?

| Product | Battery |

|---|---|

| Eliminator® III LaserScope® 3-12x44mm | CR123A |

| Eliminator IV & Eliminator V | 2 x AAA |

| Eliminator IV & Eliminator V Remote | CR2032 |

| Fullfield E1™ Riflescope 3-9x40mm, only item 200322 (with rotary dial) | CR2032 |

| Fullfield TAC30™ Riflescope 1-4x24mm | CR2032 |

| SkullTac™ Riflescope 1-4x24mm | CR2032 |

| XTR II™ Riflescope | CR2032 |

| AR-1X™ | AA |

| AR-332™ | CR2032 |

| AR-536™ | CR2032 |

| FastFire™ 2 | CR2032 |

| FastFire™ 3 | CR1632 |

| FastFire™ 4 | CR1632 |

| AR-F3™ 3 MOA | CR1632 |

| All SpeedBead™ Systems | CR1632 |

| RT-1 / RT-3 / RT-5 | CR2032 |

| FastFire RD | AAA |

| RT-6 | CR2032 |

| Oracle X | CR123A |

| Oracle X Remote | CR2032 |

| Oracle 1 & Oracle 2 | CR123A |

| Fullfield IV (Illuminated Models Only) | CR2032 |

| Signature HD (Illuminated Models Only) | CR2032 |

| XTR PRO | CR2032 |

| XTR III (Illuminated Models Only) | CR2032 |

| BTS 35 & BTS 50 | 18650 |

| BTC 35 & BTC 50 | 2x CR123A |

| Signature LRF 10x42 Binoculars | CR2 |

| Signature LRF 2000 | CR2 |

What should I use to clean my optics?

- Carefully remove any debris before cleaning the lenses, to prevent scratching.

- Use an air can or soft brush to remove dirt or dust from the lenses.

- Then use a cotton-tipped swab with rubbing alcohol applied to remove any debris remaining along the edge of the optics.

- With another cotton-tipped swab and alcohol, start at the center of the lens and make a circular motion. Increase the circle size each time until you reach the edge of the lens. Multiple swabs may be needed.

- Next use a clean cotton-tipped swab (with no alcohol) to remove any remaining residue from the lens.

For in-field cleaning, we recommend using the Burris lens pen.

Always use scope caps to protect from debris and scratches on the lens.

Can my scope be refinished?

Unfortunately, no. Ring marks are usually the reason owners want to refinish scopes. To prevent ring marks, we recommend…

- Using Signature Rings™

- Following the torque specs of the rings

- Lapping to prevent ring marks

How do I focus my scope?

There are 2 types of eyepieces on Burris scopes. One has a lock-ring system and the other is on the end of a European-style eyepiece. European-style eyepieces include: Euro Diamonds, Black Diamonds, Fullfield II™, Fullfield II Tactical, Fullfield 30™, Fullfield TAC30™, and XTR™.

To focus a lock-ring scope…

- Grasp the knurled eyepiece lock ring and loosen by turning the eyepiece counterclockwise.

- Turn the lock ring clockwise away from the eyepiece.

- Look through the scope at a white wall. Turn the eyepiece until the reticle appears sharp.

- Look away from the scope. Now look through the scope again. If the reticle is still in focus, go to step 6.

- If the reticle is not in focus, repeat steps 3 and 4 until the scope is in focus.

- When you are satisfied with your focus, tighten the lock ring firmly against the eyepiece.

To focus a European-style eyepiece…

- Look through the scope at a white wall.

- Grasp the rubber eye guard at the end of your eyepiece. Turn the rubber eye guard clockwise all the way against the eyepiece.

- Now turn it counterclockwise until the reticle appears sharp.

- Look away from the scope. Now look through the scope again. If the reticle is still in focus, the process is complete.

- If the reticle is not in focus, repeat steps 1 through 4 until the scope is in focus.

Your scope only needs to be focused once. However, each person’s vision is different, so a scope may need to be refocused when changing users.

How do I know how much to tighten the rings and bases?

Use these specifications, being careful not to over-tighten and damage your product:

| AR-P.E.P.R.™ / XTR Ring Tops | 20 inch-pounds |

| AR-P.E.P.R. / XTR Ring Crossbolt | 65 inch-pounds |

| Eliminator Mounting Clamps | 65 inch-pounds |

| FastFire Picatinny Mount Crossbolt | 20 inch-pounds |

| Rimfire/ Airgun Base Clamps | 40 inch-pounds |

| Rimfire / Airgun Rings Tops | 20 inch-pounds |

| Rear Windage Base Screws | 40 inch-pounds |

| Base Screws | 30 inch-pounds |

| Signature Zee Rings™ / Zee Ring Crossbolt | 30 inch-pounds |

| Signature / Zee Ring / Tikka Ring / CZ Ring Tops | 20 inch-pounds |

| Tikka / CZ Crossbolt | 60 inch-pounds |

| Thermal Riflescope | 60 inch-pounds |

| FastFire to Mount Screws | 12 inch-pounds |

| Oracle X Mount to Scope | 45 inch-pounds |

| Oracle X Crossbolt | 55 inch-pounds |

| Oracle X Mount Locking Screws | Finger Tight |

| 1/2" Picatinny Riser | 40 inch-pounds |

| AR-F3 Crossbolt | 20 inch-pounds |

| AR-F3 Optic to Mount screws | 12 inch-pounds |

| AR-F4 Cross Bolt | 40 inch-pounds |

| AR-F4 Optic to Mount Screws | 12 inch-pounds |

| AR-332/AR-536 Crossbolt | 65 inch-pounds |

| AR-332/AR-536 Base to Optic | 45 inch-pounds |

| RT-1/ RT-3/ RT-5 Crossbolt | 45 inch-pounds |

| RT-1 Mount to Optic Screws | 15 inch-pounds |

| XTR Signature Ring Clamps | 45 inch-pounds |

| XTR Signature Ring Tops | 20 inch-pounds |

How do I mechanically center my scope?

- Turn the elevation adjustment dial all the way to the top. Do not force it.

- Now turn this same dial down, counting each click until you reach the bottom.

- Divide the number in half and click the scope back to that number. (So if you counted 100, click the scope back to 50.)

- Repeat these steps with the windage dial.

My scope adjustments are maxed out. How do I obtain more adjustment?

This is typically an issue of alignment on the firearm itself, rather than a scope defect. Many variances can cause this alignment issue: bases, rings, drill-and-tapped holes, or threading-in of the barrel at an angle.

There are many ways to correct these alignment issues.

- If it is a windage issue, use windage adjustable bases.

- If it is an elevation issue, shim the base.

- You can also use Burris Signature Rings™ to correct both windage and elevation issues. They will also hold 30% more service area of your scopes tube, and the inserts do not damage your scopes tube.

More information:

Many people notice this issue when upgrading from a lesser-quality scope on a rifle they’ve had for many years. Lesser-quality scopes have much smaller internal parts, allowing for more adjustment travel. Higher-quality optics like Burris use larger internal lenses. That gives the scope better optic quality but limits the travel more. All maximum adjustment travel specifications are clearly advertised and vary from scope to scope.

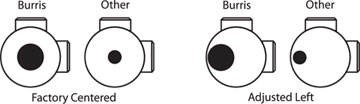

To illustrate: There are 2 tubes, one inside the other, which hold all the erector lenses. Moving the adjustments up or down eventually pushes the internal tube against the outer tube wall. See the illustrations showing how a lesser-quality scope can have more adjustment.

How do I mechanically center my scope?

- Turn the elevation adjustment dial all the way to the top. Do not force it.

- Now turn this same dial down, counting each click until you reach the bottom.

- Divide the number in half and click the scope back to that number. (So, if you counted 100, click the scope back to 50.)

- Repeat these steps with the windage dial.

Can I store my weapon in my vehicle with a scope mounted?

Try to take your firearms or bows into your home daily to prevent these issues:

- Prolonged periods of time with fluctuating temperatures can affect your scope’s seals and lubricants.

- Vibrations from bumpy roads can cause scope mounts and rings to loosen, creating point-of-impact issues.

Why does my reticle move down when my turret says UP?

When adjusting your turrets, focus on altering the bullet's impact point rather than your initial aiming point. For instance, if you're aiming low and adjust the elevation turret 'up,' the reticle should physically shift downward. However, this adjustment is made so that you have to raise the barrel to realign with the target. Raising the barrel moves the point of impact upward, bringing it back on target. This process may be perplexing during the initial bore sighting of the riflescope, as it's the only time when you need to consider physically moving the reticle. Yet, once you start shooting and concentrate on shifting the bullet holes downrange rather than adjusting the reticle, it becomes much more straightforward.